Epoxy

A syringe of "5-minute" epoxy glue, containing separate compartments for the epoxy resin and the hardener.

Structure of the highly reactive epoxide group present in all epoxy resins.

Epoxy (/ə-POCK-see/) is either any of the basic components or the cured end products of epoxy resins, as well as a colloquial name for the epoxide functional group.[1] Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (usually called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, use in electronics/electrical components/LEDs, high tension electrical insulators, paint brush manufacturing, fiber-reinforced plastic materials and structural adhesives.

Contents

1 Epoxy resin

1.1 Bisphenol A epoxy resin

1.2 Bisphenol F epoxy resin

1.3 Novolac epoxy resin

1.4 Cycloaliphatic epoxy resin

1.5 Epoxy resin diluents

1.6 Glycidylamine epoxy resin

2 Curing epoxy resins

2.1 Homopolymerisation

2.2 Amines

2.3 Anhydrides

2.4 Phenols

2.5 Thiols

3 History

4 Applications

4.1 Paints and coatings

4.2 Adhesives

4.3 Industrial tooling and composites

4.4 Wind Turbine Technology composites

4.5 Electrical systems and electronics

4.6 Petroleum & petrochemical

4.7 Consumer and marine applications

4.8 Aerospace applications

4.9 Biology

4.10 Art

5 Industry

6 Health risks

7 See also

8 References

9 External links

Epoxy resin

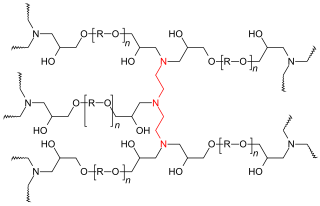

Structure of a cured epoxy glue. The triamine hardener is shown in red, the resin in black. The resin's epoxide groups have reacted with the hardener and are not present anymore. The material is highly crosslinked and contains many OH groups, which confer adhesive properties.

Epoxy resins are low molecular weight pre-polymers or higher molecular weight polymers which normally contain at least two epoxide groups. The epoxide group is also sometimes referred to as a glycidyl or oxirane group.

A wide range of epoxy resins are produced industrially. The raw materials for epoxy resin production are today largely petroleum derived, although some plant derived sources are now becoming commercially available (e.g. plant derived glycerol used to make epichlorohydrin).

Epoxy resins are polymeric or semi-polymeric materials or an Oligomer, and as such rarely exist as pure substances, since variable chain length results from the polymerisation reaction used to produce them. High purity grades can be produced for certain applications, e.g. using a distillation purification process. One downside of high purity liquid grades is their tendency to form crystalline solids due to their highly regular structure, which require melting to enable processing.

An important criterion for epoxy resins is the epoxide group content. This is correctly expressed as the specific amount of substance of epoxide groups in the material B under consideration, calculated as the ratio of the amount of substance of epoxide groups in this material B, n(EP), divided by the mass m(B) of the material B under consideration, in this case, the mass of the resin. The SI unit for this quantity is "mol/kg", or multiples thereof. Deprecated quantities which are still in use are the so-called "epoxide number" which is (not a number and should therefore not be referred to as such, but) the ratio of the amount of substance of epoxide groups, n(EP), and the mass m(B) of the material B, with the SI unit "mol/kg", or the so-called "epoxide equivalent weight", which is the ratio of the mass of a sample B of the resin and the amount of substance of epoxide groups present in that sample B, with the SI unit "kg/mol". The so-called "epoxide equivalent weight" is simply the inverse of the so-called "epoxide number".

The specific amount of substance of epoxide groups is used to calculate the mass of co-reactant (hardener) to use when curing epoxy resins. Epoxies are typically cured with stoichiometric or near-stoichiometric quantities of curative to achieve maximum physical properties.

As with other classes of thermoset polymer materials, blending different grades of epoxy resin, as well as use of additives, plasticizers or fillers is common to achieve the desired processing or final properties, or to reduce cost. Use of blending, additives and fillers is often referred to as formulating.

Bisphenol A epoxy resin

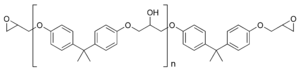

Important epoxy resins are produced from combining epichlorohydrin and bisphenol A to give bisphenol A diglycidyl ethers.

Structure of bisphenol-A diglycidyl ether epoxy resin: n denotes the number of polymerized subunits and is typically in the range from 0 to 25

Increasing the ratio of bisphenol A to epichlorohydrin during manufacture produces higher molecular weight linear polyethers with glycidyl end groups, which are semi-solid to hard crystalline materials at room temperature depending on the molecular weight achieved. This route of synthesis is known as the Taffy process. More modern manufacturing methods of higher molecular weight epoxy resins is to start with Liquid Epoxy Resin (LER) and add a calculated amount of Bisphenol A and then a catalyst is added and the reaction heated to circa 160 °C. This process is known as advancement.[2] There are numerous patents and articles on this process which has been popular for over 20 years. As the molecular weight of the resin increases, the epoxide content reduces and the material behaves more and more like a thermoplastic. Very high molecular weight polycondensates (ca. 30 000 – 70 000 g/mol) form a class known as phenoxy resins and contain virtually no epoxide groups (since the terminal epoxy groups are insignificant compared to the total size of the molecule). These resins do however contain hydroxyl groups throughout the backbone, which may also undergo other cross-linking reactions, e.g. with aminoplasts, phenoplasts and isocyanates.

Bisphenol F epoxy resin

Bisphenol F may undergo epoxy resin formation in a similar fashion to bisphenol A. These resins typically have lower viscosity and a higher mean epoxy content per gramme than bisphenol A resins, which (once cured) gives them increased chemical resistance.

Novolac epoxy resin

Reaction of phenols with formaldehyde and subsequent glycidylation with epichlorohydrin produces epoxidised novolacs, such as epoxy phenol novolacs (EPN) and epoxy cresol novolacs (ECN). These are highly viscous to solid resins with typical mean epoxide functionality of around 2 to 6. The high epoxide functionality of these resins forms a highly crosslinked polymer network displaying high temperature and chemical resistance, but low flexibility.

Cycloaliphatic epoxy resin

A related class is cycloaliphatic epoxy resin, which contains one or more cycloaliphatic rings in the molecule (e.g. 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexane carboxylate). This class also displays lower viscosity at room temperature, but offers significantly higher temperature resistance than the aliphatic epoxy diluents. However, reactivity is rather low compared to other classes of epoxy resin, and high temperature curing using suitable accelerators is normally required. As aromaticity is not present in these materials as it is in Bisphenol A and F resins, the UV stability is considerably improved.

Epoxy resin diluents

Epoxy resins diluents are typically formed by glycidylation of aliphatic alcohols or polyols. The resulting materials may be monofunctional (e.g. dodecanol glycidyl ether), difunctional (butanediol diglycidyl ether), or higher functionality (e.g. trimethylolpropane triglycidyl ether). These resins typically display low viscosity at room temperature (10-200 mPa.s) and are often referred to as reactive diluents. They are rarely used alone, but are rather employed to modify (reduce) the viscosity of other epoxy resins. This has led to the term ‘modified epoxy resin’ to denote those containing viscosity-lowering reactive diluents.

Glycidylamine epoxy resin

Glycidylamine epoxy resins are higher functionality epoxies which are formed when aromatic amines are reacted with epichlorohydrin. Important industrial grades are triglycidyl-p-aminophenol (functionality 3) and N,N,N′,N′-tetraglycidyl-bis-(4-aminophenyl)-methane (functionality 4). The resins are low to medium viscosity at room temperature, which makes them easier to process than EPN or ECN resins. This coupled with high reactivity, plus high temperature resistance and mechanical properties of the resulting cured network makes them important materials for aerospace composite applications.

Curing epoxy resins

In general, uncured epoxy resins have only poor mechanical, chemical and heat resistance properties. However, good properties are obtained by reacting the linear epoxy resin with suitable curatives to form three-dimensional cross-linked thermoset structures. This process is commonly referred to as curing or gelation process.[3] Curing of epoxy resins is an exothermic reaction and in some cases produces sufficient heat to cause thermal degradation if not controlled.

Curing may be achieved by reacting an epoxy with itself (homopolymerisation) or by forming a copolymer with polyfunctional curatives or hardeners. In principle, any molecule containing a reactive hydrogen may react with the epoxide groups of the epoxy resin. Common classes of hardeners for epoxy resins include amines, acids, acid anhydrides, phenols, alcohols and thiols. Relative reactivity (lowest first) is approximately in the order: phenol < anhydride < aromatic amine < cycloaliphatic amine < aliphatic amine < thiol.

While some epoxy resin/ hardener combinations will cure at ambient temperature, many require heat, with temperatures up to 150 °C being common, and up to 200 °C for some specialist systems. Insufficient heat during cure will result in a network with incomplete polymerisation, and thus reduced mechanical, chemical and heat resistance. Cure temperature should typically attain the glass transition temperature (Tg) of the fully cured network in order to achieve maximum properties. Temperature is sometimes increased in a step-wise fashion to control the rate of curing and prevent excessive heat build-up from the exothermic reaction.

Hardeners which show only low or limited reactivity at ambient temperature, but which react with epoxy resins at elevated temperature are referred to as latent hardeners. When using latent hardeners, the epoxy resin and hardener may be mixed and stored for some time prior to use, which is advantageous for many industrial processes. Very latent hardeners enable one-component (1K) products to be produced, whereby the resin and hardener are supplied pre-mixed to the end user and only require heat to initiate curing. One-component products generally have shorter shelf-lives than standard 2-component systems, and products may require cooled storage and transport.

The epoxy curing reaction may be accelerated by addition of small quantities of accelerators. Tertiary amines, carboxylic acids and alcohols (especially phenols) are effective accelerators. Bisphenol A is a highly effective and widely used accelerator, but is now increasingly replaced due to health concerns with this substance.

Homopolymerisation

Epoxy resin may be reacted with itself in the presence of an anionic catalyst (a Lewis base such as tertiary amines or imidazoles) or a cationic catalyst (a Lewis acid such as a boron trifluoride complex) to form a cured network. This process is known as catalytic homopolymerisation. The resulting network contains only ether bridges, and exhibits high thermal and chemical resistance, but is brittle and often requires elevated temperature for the curing process, so finds only niche applications industrially.

Epoxy homopolymerisation is often used when there is a requirement for UV curing, since cationic UV catalysts may be employed (e.g. for UV coatings).

Amines

Polyfunctional primary amines form an important class of epoxy hardeners. Primary amines undergo an addition reaction with the epoxide group to form a hydroxyl group and a secondary amine. The secondary amine can further react with an epoxide to form a tertiary amine and an additional hydroxyl group. Kinetic studies have shown the reactivity of the primary amine to be approximately double that of the secondary amine. Use of a difunctional or polyfunctional amine forms a three-dimensional cross-linked network.

Aliphatic, cycloaliphatic and aromatic amines are all employed as epoxy hardeners. Amine type hardeners will alter both the processing properties (viscosity, reactivity) and the final properties (mechanical, temperature and heat resistance) of the cured copolymer network. Thus amine structure is normally selected according to the application. Overall reactivity potential for different hardeners can roughly be ordered; aliphatic amines > cycloaliphatic amines > aromatic amines, though aliphatic amines with steric hindrance near the amino groups may react as slowly as some of the aromatic amines. Slower reactivity allows longer working times for processors. Temperature resistance generally increases in the same order, since aromatic amines form much more rigid structures than aliphatic amines. Aromatic amines were widely used as epoxy resin hardeners, due to the excellent end properties when mixed with a parent resin. Over the past few decades concern about the possible adverse health effects of many aromatic amines has lead the increased use of aliphatic or cycloaliphatic amine alternatives.

Structure of TETA, a typical hardener. The amine (NH2) groups react with the epoxide groups of the resin during polymerisation.

Anhydrides

Epoxy resins may be cured with cyclic anhydrides at elevated temperatures. Reaction occurs only after opening of the anhydride ring, e.g. by secondary hydroxyl groups in the epoxy resin. A possible side reaction may also occur between the epoxide and hydroxyl groups, but this may suppressed by addition of tertiary amines.

The low viscosity and high latency of anhydride hardeners makes them suitable for processing systems which require addition of mineral fillers prior to curing, e.g. for high voltage electrical insulators.

Phenols

Polyphenols, such as bisphenol A or novolacs can react with epoxy resins at elevated temperatures (130-180 °C 266-356 °F), normally in the presence of a catalyst. The resulting material has ether linkages and displays higher chemical and oxidation resistance than typically obtained by curing with amines or anhydrides.

Since many novolacs are solids, this class of hardeners is often employed for powder coatings.

Thiols

Also known as mercaptans, thiols contain a sulfur which reacts very readily with the epoxide group, even at ambient or sub-ambient temperatures. While the resulting network does not typically display high temperature or chemical resistance, the high reactivity of the thiol group makes it useful for applications where heated curing is not possible, or very fast cure is required e.g. for domestic DIY adhesives and chemical rock bolt anchors. Thiols have a characteristic odour, which can be detected in many two-component household adhesives.

History

Condensation of epoxides and amines was first reported and patented by Paul Schlack of Germany in 1934.[4] Claims of discovery of bisphenol-A-based epoxy resins include Pierre Castan[5] in 1943. Castan's work was licensed by Ciba, Ltd. of Switzerland, which went on to become one of the three major epoxy resin producers worldwide. Ciba's epoxy business was spun off as Vantico in the late 1990s, which was subsequently sold in 2003 and became the Advanced Materials business unit of Huntsman Corporation of the United States. In 1946, Sylvan Greenlee, working for the Devoe & Raynolds Company, patented resin derived from bisphenol-A and epichlorohydrin.[6] Devoe & Raynolds, which was active in the early days of the epoxy resin industry, was sold to Shell Chemical; the division involved in this work was eventually sold, and via a series of other corporate transactions is now part of Hexion Inc..[7]

Applications

The applications for epoxy-based materials are extensive and include coatings, adhesives and composite materials such as those using carbon fiber and fiberglass reinforcements (although polyester, vinyl ester, and other thermosetting resins are also used for glass-reinforced plastic). The chemistry of epoxies and the range of commercially available variations allows cure polymers to be produced with a very broad range of properties. In general, epoxies are known for their excellent adhesion, chemical and heat resistance, good-to-excellent mechanical properties and very good electrical insulating properties. Many properties of epoxies can be modified (for example silver-filled epoxies with good electrical conductivity are available, although epoxies are typically electrically insulating). Variations offering high thermal insulation, or thermal conductivity combined with high electrical resistance for electronics applications, are available.[8]

Paints and coatings

Two part epoxy coatings were developed for heavy duty service on metal substrates and use less energy than heat-cured powder coatings. These systems provide a tough, protective coating with excellent hardness. Some epoxy coatings are formulated as an emulsion in water, and can be cleaned up without solvents. Epoxy coatings are often used in industrial and automotive applications since they are more heat resistant than latex-based and alkyd-based paints. Epoxy paints tend to deteriorate, known as "chalking out", due to UV exposure.[9]

Polyester epoxies are used as powder coatings for washers, driers and other "white goods". Fusion Bonded Epoxy Powder Coatings (FBE) are extensively used for corrosion protection of steel pipes and fittings used in the oil and gas industry, potable water transmission pipelines (steel), and concrete reinforcing rebar. Epoxy coatings are also widely used as primers to improve the adhesion of automotive and marine paints especially on metal surfaces where corrosion (rusting) resistance is important. Metal cans and containers are often coated with epoxy to prevent rusting, especially for foods like tomatoes that are acidic. Epoxy resins are also used for decorative flooring applications such as terrazzo flooring, chip flooring, and colored aggregate flooring.

Epoxies were modified in a variety of ways, Reacted with fatty acids derived from oils to yield epoxy esters, which were cured the same way as alkyds . Typical ones were L8(80% linseed, D4 (40% Dehydrated castor oil). These were often reacted with styrene to make styrenated epoxy esters, used as primers. Curing with phenolics to make drum linings, curing esters with amine resins and pre-curing epoxies with amino resins to make resistant top coats.

One of the best examples was a system of using solvent free epoxies for priming ships during construction, this used a system of hot airless spray with premixing at the head. This obviated the problem of solvent retention under the film, which caused adhesion problems later on.

Adhesives

Special epoxy is strong enough to withstand the forces between a surfboard fin and the fin mount. This epoxy is waterproof and capable of curing underwater. The blue-coloured epoxy on the left is still undergoing curing.

Epoxy adhesives are a major part of the class of adhesives called "structural adhesives" or "engineering adhesives" (that includes polyurethane, acrylic, cyanoacrylate, and other chemistries.) These high-performance adhesives are used in the construction of aircraft, automobiles, bicycles, boats, golf clubs, skis, snowboards, and other applications where high strength bonds are required. Epoxy adhesives can be developed to suit almost any application. They can be used as adhesives for wood, metal, glass, stone, and some plastics. They can be made flexible or rigid, transparent or opaque/colored, fast setting or slow setting. Epoxy adhesives are better in heat and chemical resistance than other common adhesives. In general, epoxy adhesives cured with heat will be more heat- and chemical-resistant than those cured at room temperature. The strength of epoxy adhesives is degraded at temperatures above 350 °F (177 °C).[10]

Some epoxies are cured by exposure to ultraviolet light. Such epoxies are commonly used in optics, fiber optics, and optoelectronics.

Industrial tooling and composites

Epoxy systems are used in industrial tooling applications to produce molds, master models, laminates, castings, fixtures, and other industrial production aids. This "plastic tooling" replaces metal, wood and other traditional materials, and generally improves the efficiency and either lowers the overall cost or shortens the lead-time for many industrial processes. Epoxies are also used in producing fiber-reinforced or composite parts. They are more expensive than polyester resins and vinyl ester resins, but usually produce stronger and more temperature-resistant thermoset polymer matrix composite parts.

Wind Turbine Technology composites

A growing use of epoxy resins is in the fabrication of wind turbine blades.[11]

Electrical systems and electronics

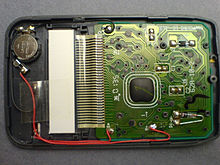

An epoxy encapsulated hybrid circuit on a printed circuit board.

The interior of a pocket calculator. The dark lump of epoxy in the center covers the processor chip

Epoxy resin formulations are important in the electronics industry, and are employed in motors, generators, transformers, switchgear, bushings, insulators, printed wiring boards (PWB), and semiconductor encapsulants. Epoxy resins are excellent electrical insulators and protect electrical components from short circuiting, dust and moisture. In the electronics industry epoxy resins are the primary resin used in overmolding integrated circuits, transistors and hybrid circuits, and making printed circuit boards. The largest volume type of circuit board—an "FR-4 board"—is a sandwich of layers of glass cloth bonded into a composite by an epoxy resin. Epoxy resins are used to bond copper foil to circuit board substrates, and are a component of the solder mask on many circuit boards.

Flexible epoxy resins are used for potting transformers and inductors. By using vacuum impregnation on uncured epoxy, winding-to-winding, winding-to-core, and winding-to-insulator air voids are eliminated. The cured epoxy is an electrical insulator and a much better conductor of heat than air. Transformer and inductor hot spots are greatly reduced, giving the component a stable and longer life than unpotted product.

Epoxy resins are applied using the technology of resin dispensing.

Petroleum & petrochemical

Epoxies can be used to plug selective layers in a reservoir which are producing excessive brine. The technique is named "water shut-off treatment".[3]

Consumer and marine applications

Epoxies are sold in hardware stores, typically as a pack containing separate resin and hardener, which must be mixed immediately before use. They are also sold in boat shops as repair resins for marine applications. Epoxies typically are not used in the outer layer of a boat because they deteriorate by exposure to UV light. They are often used during boat repair and assembly, and then over-coated with conventional or two-part polyurethane paint or marine-varnishes that provide UV protection.

There are two main areas of marine use. Because of the better mechanical properties relative to the more common polyester resins, epoxies are used for commercial manufacture of components where a high strength/weight ratio is required. The second area is that their strength, gap filling properties and excellent adhesion to many materials including timber have created a boom in amateur building projects including aircraft and boats.

Normal gelcoat formulated for use with polyester resins and vinylester resins does not adhere to epoxy surfaces, though epoxy adheres very well if applied to polyester resin surfaces. "Flocoat" that is normally used to coat the interior of polyester fibreglass yachts is also compatible with epoxies.

Epoxy materials tend to harden somewhat more gradually, while polyester materials tend to harden quickly, particularly if a lot of catalyst is used.[12] The chemical reactions in both cases are exothermic. Large quantities of mix will generate their own heat and greatly speed the reaction, so it is usual to mix small amounts which can be used quickly.

While it is common to associate polyester resins and epoxy resins, their properties are sufficiently different that they are properly treated as distinct materials. Polyester resins are typically low strength unless used with a reinforcing material like glass fibre, are relatively brittle unless reinforced, and have low adhesion. Epoxies, by contrast, are inherently strong, somewhat flexible and have excellent adhesion. However, polyester resins are much cheaper.

Epoxy resins typically require a precise mix of two components which form a third chemical. Depending on the properties required, the ratio may be anything from 1:1 or over 10:1, but in every case they must be mixed exactly. The final product is then a precise thermo-setting plastic. Until they are mixed the two elements are relatively inert, although the 'hardeners' tend to be more chemically active and should be protected from the atmosphere and moisture. The rate of the reaction can be changed by using different hardeners, which may change the nature of the final product, or by controlling the temperature.

By contrast, polyester resins are usually made available in a 'promoted' form, such that the progress of previously-mixed resins from liquid to solid is already underway, albeit very slowly. The only variable available to the user is to change the rate of this process using a catalyst, often Methyl-Ethyl-Ketone-Peroxide (MEKP), which is very toxic. The presence of the catalyst in the final product actually detracts from the desirable properties, so that small amounts of catalyst are preferable, so long as the hardening proceeds at an acceptable pace. The rate of cure of polyesters can therefore be controlled by the amount and type of catalyst as well as by the temperature.

As adhesives, epoxies bond in three ways: a) Mechanically, because the bonding surfaces are roughened; b) by proximity, because the cured resins are physically so close to the bonding surfaces that they are hard to separate; c) ionically, because the epoxy resins form ionic bonds at an atomic level with the bonding surfaces. This last is substantially the strongest of the three. By contrast, polyester resins can only bond using the first two of these, which greatly reduces their utility as adhesives and in marine repair.

Aerospace applications

In the aerospace industry, epoxy is used as a structural matrix material which is then reinforced by fiber. Typical fiber reinforcements include glass, carbon, Kevlar, and boron.

Epoxies are also used as a structural glue. Materials like wood, and others that are 'low-tech' are glued with epoxy resin.

Biology

Water-soluble epoxies such as Durcupan[13][14]

are commonly used for embedding

electron microscope samples in plastic so they may be sectioned (sliced thin) with a microtome and then imaged.[15]

Art

Epoxy resin, mixed with pigment, may be used as a painting medium, by pouring layers on top of each other to form a complete picture.[16] It is also used in jewelry, as a doming resin for decorations and labels, and in decoupage type applications for art, countertops, and tables.

Industry

As of 2006, the epoxy industry amounts to more than US$5 billion in North America and about US$15 billion worldwide. The Chinese market has been growing rapidly, and accounts for more than 30% of the total worldwide market. It is made up of approximately 50–100 manufacturers of basic or commodity epoxy resins and hardeners.

These commodity epoxy manufacturers mentioned above typically do not sell epoxy resins in a form usable to smaller end users, so there is another group of companies that purchase epoxy raw materials from the major producers and then compounds (blends, modifies, or otherwise customizes) epoxy systems from these raw materials. These companies are known as "formulators". The majority of the epoxy systems sold are produced by these formulators and they comprise over 60% of the dollar value of the epoxy market. There are hundreds of ways that these formulators can modify epoxies—by adding mineral fillers (talc, silica, alumina, etc.), by adding flexibilizers, viscosity reducers, colorants, thickeners, accelerators, adhesion promoters, etc. These modifications are made to reduce costs, to improve performance, and to improve processing convenience. As a result, a typical formulator sells dozens or even thousands of formulations—each tailored to the requirements of a particular application or market.

Impacted by the global economic slump, the epoxy market size declined to $15.8 billion in 2009, almost to the level of 2005. In some regional markets it even decreased nearly 20%. The current epoxy market is experiencing positive growth as the global economy revives. With an annual growth rate of 3.5 - 4% the epoxy market is expected to reach $17.7 billion by 2012 and $21.35 billion by 2015. Higher growth rate is foreseen thereafter due to stronger demands from epoxy composite market and epoxy adhesive market.[17]

Health risks

The primary risk associated with epoxy use is often related to the hardener component and not to the epoxy resin itself. Amine hardeners in particular are generally corrosive, but may also be classed as toxic or carcinogenic/mutagenic. Aromatic amines present a particular health hazard (most are known or suspected carcinogens), but their use is now restricted to specific industrial applications, and safer aliphatic or cycloaliphatic amines are commonly employed.

Liquid epoxy resins in their uncured state are mostly classed as irritant to the eyes and skin, as well as toxic to aquatic organisms. Solid epoxy resins are generally safer than liquid epoxy resins, and many are classified non-hazardous materials. One particular risk associated with epoxy resins is sensitization. The risk has been shown to be more pronounced in epoxy resins containing low molecular weight epoxy diluents.[18] Exposure to epoxy resins can, over time, induce an allergic reaction. Sensitization generally occurs due to repeated exposure (e.g. through poor working hygiene or lack of protective equipment) over a long period of time. Allergic reaction sometimes occurs at a time which is delayed several days from the exposure. Allergic reaction is often visible in the form of dermatitis, particularly in areas where the exposure has been highest (commonly hands and forearms). Epoxy use is a main source of occupational asthma among users of plastics.[19]Bisphenol A, which is used to manufacture a common class of epoxy resins, is a known endocrine disruptor.

See also

- Thermosetting polymer

- Thermoset polymer matrix

- Plastic

References

^ Clayton May (11 May 2018). Epoxy Resins: Chemistry and Technology (Second Edition). CRC Press. p. 65. ISBN 978-1-351-44995-3.Epoxies are the resins most commonly employed for electrical and electronic applications. Selection of epoxies is based on their superior adhesion, permeability, purity, and corrosion- and stress-resistance properties.

.mw-parser-output cite.citation{font-style:inherit}.mw-parser-output q{quotes:"""""""'""'"}.mw-parser-output code.cs1-code{color:inherit;background:inherit;border:inherit;padding:inherit}.mw-parser-output .cs1-lock-free a{background:url("//upload.wikimedia.org/wikipedia/commons/thumb/6/65/Lock-green.svg/9px-Lock-green.svg.png")no-repeat;background-position:right .1em center}.mw-parser-output .cs1-lock-limited a,.mw-parser-output .cs1-lock-registration a{background:url("//upload.wikimedia.org/wikipedia/commons/thumb/d/d6/Lock-gray-alt-2.svg/9px-Lock-gray-alt-2.svg.png")no-repeat;background-position:right .1em center}.mw-parser-output .cs1-lock-subscription a{background:url("//upload.wikimedia.org/wikipedia/commons/thumb/a/aa/Lock-red-alt-2.svg/9px-Lock-red-alt-2.svg.png")no-repeat;background-position:right .1em center}.mw-parser-output .cs1-subscription,.mw-parser-output .cs1-registration{color:#555}.mw-parser-output .cs1-subscription span,.mw-parser-output .cs1-registration span{border-bottom:1px dotted;cursor:help}.mw-parser-output .cs1-hidden-error{display:none;font-size:100%}.mw-parser-output .cs1-visible-error{font-size:100%}.mw-parser-output .cs1-subscription,.mw-parser-output .cs1-registration,.mw-parser-output .cs1-format{font-size:95%}.mw-parser-output .cs1-kern-left,.mw-parser-output .cs1-kern-wl-left{padding-left:0.2em}.mw-parser-output .cs1-kern-right,.mw-parser-output .cs1-kern-wl-right{padding-right:0.2em}

^ "Epoxy resin mixtures containing advancement catalysts" (PDF). freepatentsonline.com. Retrieved 2018-08-29.

^ ab Hakiki, Farizal et al. (2015). Is Epoxy-Based Polymer Suitable for Water Shut-Off Application? SPE-176457-MS. SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, 20–22 October, Nusa Dua, Bali, Indonesia. doi: 10.2118/176457-MS

^ P. Schlack, I. G. Farbenindustrie, German Patent 676 117 (1938), US Patent 2 136 928 (1938).

^ US 2444333, Pierre Castan, "Process for the manufacture of thermosetting synthetic resins by the polymerization of alkylene oxide derivatives", issued 1948-06-29, assigned to DeVoe & Raynolds

^ US 2456408, Sylvan Owen Greenlee, "Synthetic drying compositions", issued 1948-12-14, assigned to DeVoe & Raynolds

^ "History of Epoxy Resin". epoxyflooringtech.com.

^ May, Clayton A. (1987-12-23). Epoxy Resins: Chemistry and Technology (Second ed.). New York: Marcel Dekker Inc. p. 794. ISBN 0-8247-7690-9.

^ Bayliss, D.A.; Deacon, D.H. (2002). Steelwork corrosion control (2nd ed.). London: Spon. pp. 13.6.6 Chalking. ISBN 978-0-415-26101-2.

^ Morena, John J (1988). Advanced Composite Mold Making. New York: Van Nostrand Reinhold Co. Inc. pp. 124–125. ISBN 978-0-442-26414-7.

^ "Technical Advances in Epoxy Technology for Wind Turbine Blade Fabrication" (PDF).

^ Hakiki, F., Nuraeni, N., Salam, D.D., Aditya, W., Akbari, A., Mazrad, Z.A.I. and Siregar, S. Preliminary Study on Epoxy-Based Polymer for Water Shut-Off Application. Paper IPA15-SE-025. Proceeding of The 39th IPA Conference and Exhibition, Jakarta, Indonesia, May 2015.

^ Stäubli, W. (1963). "A new embedding technique for electron microscopy, combining a water-soluble epoxy resin (Durcupan) with water-insoluble Araldite" (PDF). The Journal of Cell Biology. Rockefeller Univ Press. 16 (1): 197. doi:10.1083/jcb.16.1.197. PMC 2106182.

^ Kushida, H. (1963). "A Modification of the Water-miscible Epoxy Resin "Durcupan" Embedding Method for Ultrathin Sectioning". Journal of Electron Microscopy. Japan Society Microscopy. 12 (1): 72.

^ Luft, J.H. (1961). "Improvements in epoxy resin embedding methods" (PDF). The Journal of Biophysical and Biochemical Cytology. 9 (2). Rockefeller Univ Press. p. 409.

^ McCreight, Tim; Bsullak, Nicole (2001). Color on Metal: 50 Artists Share Insights and Techniques. Guild Pub. ISBN 978-1-893164-06-2.

^ "Market Report: World Epoxy Resin Market". Acmite Market Intelligence. External link in|publisher=(help)

^ [1] An assessment of skin sensitisation by the use of epoxy resin in the construction industry, 2003

^ MayoClinic --> Occupational asthma May 23, 2009

External links

| Look up epoxy in Wiktionary, the free dictionary. |

Epoxy Resin health hazards (California Department of Health Services) 21 April 2008 @ Wayback Machine https://web.archive.org/web/20080421095718/http://www.dhs.ca.gov/ohb/HESIS/epoxy.htm

The chemistry of epoxide, simple to understand